Restoration Projects

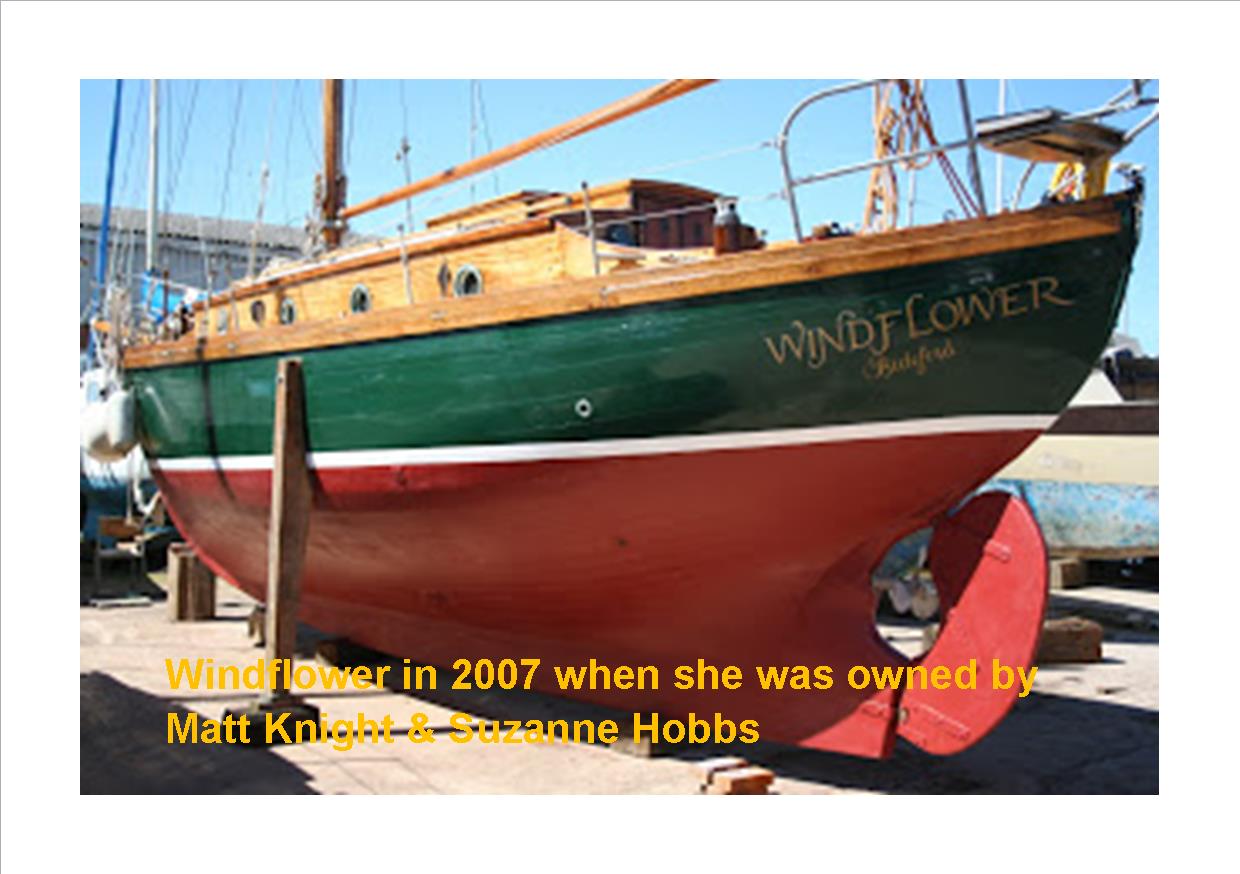

Windflower

8 Ton Sloop

LOA : 30' LWL : 27' Beam : 9' 1" Draught : 4' 9" Displacement : 8 tons TM

Lloyds Registered : N° 163440

Rob McCall is selling his 1933 8 ton sloop Windflower. He has owned her for 2 years and

although he has not been able to give her the time and investment she needs she has not

deteriorated in his ownership - he says if she had remained as she was when he bought her,

she may not still be here today. The weather has been kept off her decks and

superstructure completely using 100% waterproof tarps with a lightweight timber custom tent

frame beneath. In this manner she has “slept in the yard” where she is currently to be found

in Llandysul, Carmarthenshire.

However she now needs to find a new home urgently.

Further details - Information Sheet

http://hillyardwindflower.blogspot.com

Rob McCall. 01584 817930 mccallroba@gmail.com

'May'

Two & a Half-Ton Sloop

From thoroughly dedicated Hillyarders

Dear HOA,

Having sold Sequoiah our 12 ton Hillyard in 2011 we were hoping to enjoy

the use of the wooden S&S 'Sage' for some years to come and that this

would be the only wooden boat we would have to

look after but a rather fateful telephone call yesterday from Peter

Lucas in Dartmouth alerted us to the 1933 21/2 tonner 'May' in need of a

good home and currently lying somewhat dejected in

Darthaven Marina. Having tracked down the current owner and getting

permission to go and have a look see, with a prodder and torch we

trekked down to the marina.

See photo attached.

The deck canvas has lifted everywhere the rigging loose and baggy (but

with some nicely varnished spars), more paint on the inside than i could

ever have imagined, but the diesel engine did turnover

and some reasonably clean and useful sails inside the boat (not sure she

has had any sails up in present ownership) A number of cracked frames

but surprisingly few soft patches we have agreed a

sale price and will be taking her over shortly.

Now to find somewhere to keep her and then try and work out what to do

with her.

Will keep you posted and you better reinstate my membership so perhaps

you could send me details.

(Oh and send for the men in the white coats)

Kind Regards

Allen

Zahura - Two & a Half

Ton

Project

Hi there folks,

Thanks for getting back

to me, it’s

very much appreciated. I’d be delighted to join the

Yahoo area. Just

send me the link to join and I’m there! I saw all the

info on the site,

and she is indeed listed.

I’d love to know a bit

more about her

history and especially how she came to get to the far

North of

Scotland! The guy that had her in Inverness

unfortunately died last

year before I got her, so I cant trace any info that

way.

I won’t be beginning

the restoration

until later in the year, but she has been covered up

nicely to conserve

her in the condition she is currently in.

I’ve just finished

restoring a Stella

yacht for my father, and have restored and built a few

clinker sailing

dinghys so it should be easy enough to take on this job,

although it is

the first carvel boat I’ll have worked on.

I’ve attached a few

pics of her that

I took before putting the cover in place to show you

what state its

in(which aint too bad really). She was purchased

initially for the

engine, a Yanmar 1gm10, that was removed and installed

into the Stella.

She is way too gorgeous to cut up though, as my old man

suggested!! I

simply couldn’t do that!

I will do her up and

put either the

Dolphin engine out of the Stella in her, or a Seagull

outboard on a

bracket on the stern.

She is Bermudan rigged,

and I need to

know the length of the mast to replace or repair it when

the time comes.

Little Hillyard For Restoration

Marcel WritesI want to sale my small boat to a boat-lover who will take the time to

remodel her.

She seriously needs to be mended, after 15 years in a garage.

The constructor was David Hillyard.

Lenght : 2, 46 meters or 8.07 ft

Width : 1, 20 meters or 3,93 ft.

Can you tell me if you know the story of this boat ?

How much can I ask for ?

I live in Brittany in south Finistere, close to Fouesnant and Port La Foret.

She was previously owned by a family of Douarnenez (close to my home) and

they use her only to go to the Tristan Island, a few meters off the coast.

Thanks for your reply.

Yours truly,

thank you

marcel@excopilote.com

Spartan - A Very Special Little Hillyard

Neil Greenfield writesneil@epsnet.co.uk

Waterwitch - 4 ton - 1935

Nigel Sherratt writes

Nutmeg - 9 Ton

http://nutmeg-restoration.blogspot.com/GIROUETTE - 4 Ton -

1937

A recent visit to

Emsworth recently resulted in a chance meeting

with Nick Gates who owns

and runs Nick Gates & Co, a traditional

workshop that

specializes in wooden boat repair and

restoration. Although looking at

another Hillyard he very kindly showed me

Girouette who's images below

tell virtually the whole story, but as I know

you Hillyarders like a

yarn. Girouette has been in the same family for nearly 50 years. She was first worked on by Nick Gates when she was taken to Combes Boatyard for restoration in the early 1990s. Following the closure of the yard, she was laid up for nine years. She is now being fully restored, with work including new deck, interior and engine.

For Services that can get you Hillyard looking like this please contact:-

Nick Gates

Nick Gates & Co

Unit B, Thornham Marina, Emsworth, Hampshire. PO10 8DD

Tel: 07957 422941; Email: nick@nickgates.co.uk

www.nickgates.co.uk

Mariposa

Be inspired by this first class restoration and superbly presented website http://www.mariposa-hillyard.co.uk/

Bunty

John Casey writes;

I own a Hillyard called Bunty. Ive been perusing through your site and found her on the "List" with her details along with another boat Joy. I bought her in 1999 and rebuilt her through the years to 2008 when she was launched in the july. I have her history from 1978 but would like to track down further details. Do you have any hints on tracking down history or have details in your records please? I sail her out of Skegness Yacht Club on the east coast of Lincolnshire. Enclosed is a pic took off the sandbanks south of skegness in 2010

Bunty (Joy 2) 1927 6 Ton

Girouette 3 ton 1936

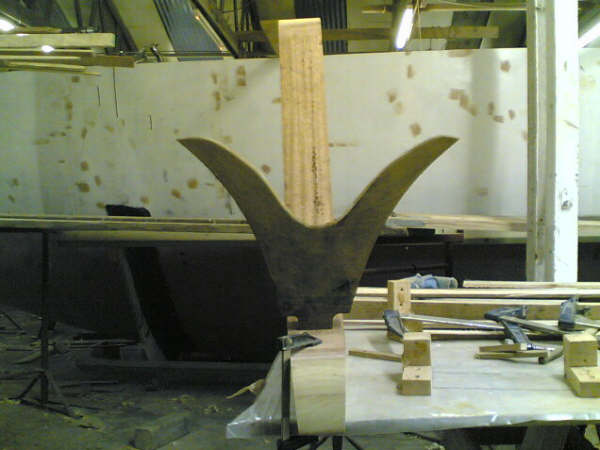

Your members may be interested to hear about Girouette, a 3 ton 1936 Hillyard that we are currently restoring. She has been owned by the French family for forty-odd years, and her restoration started back in the mid eighties at Burnes Shipyard in Bosham. That yard closed just as most of the boat had been dismantled, and she was moved to Combes Boatyard, also in Bosham, where I worked from 1987 until its closure in 1999. During that time she was almost completely reframed, the ballast keel was removed, the wooden keel and garboards replaced. A new pine T&G deck was fitted, traditionally canvassed, and trimmed in Brazilian mahogany. She was relaunched and kept in a mudberth for a few years.

When Combes closed in 1999, I moved her by road to Thornham Marina, Emsworth, where she was stored outside, but well covered, for the next nine years. During this time I have established my own business maintaining and restoring wooden boats, many of which are ex-Combes customers.

This spring we stopped up Giroutte’s dried-out hull, and relaunched her into the marina pool where she stayed afloat (after a fashion!) for most of this summer. In the autumn we put her in the workshop, and have removed the now-rotten canvas deck covering. We have fitted an interface of plywood and have sheathed the deck in epoxy and glass cloth, giving a ‘canvas look’. To complete Girouette we will be fitting a new interior, engine, and refurbishing the mast and spars. Apart from the deck, we have a ‘no plywood’ policy with this type of restoration, and by using a wealth of family photographs will return her to her appearance of fifty years ago.

If any of your members are in the Chichester area they are more than welcome to pop into the workshop for a hello. If its tea break they may even be lucky!

There are some pictures of Girouette on our website, listed at the foot of the page. I do hope you find this information of interest.

Yours sincerely,

Nick Gates

nick@nickgates.co.uk

Petmar's Progress

4th August 2009

She Floats!

She floats! Petmar hardly took in any water, and only a few dribbles remain. She is floating way above her waterline, as we have removed all the internal ballast.

What a relief, and the beginning of a new stage of the repairs

3rd August 2009

After 5 months hard work on Petmar, we are relaunching her tomorrow morning! Thank you all for your advice and support during the first phase of her restauration. Next up, cabin sole, galley and recovering the cabin top, with some deck sanding, painting and varnishing thrown in.

Will post photos when I get a minute. http://groups.yahoo.com/group/hillyards/ Suffice to say she looks like a different boat now, with her new paint!

2nd July 2009

Work on Petmar is progressing well. All the planking that needed doing at the stern is done, and we will soon be moving on to the ribs. As you can see from the most recent photographs uploaded in the album, paint is beginning to cover the bare planks, and she is looking much much better.

We got a helping hand from Bernard, a shipwright who stopped in Boulogne for a couple of days, for the longuest plank that needed doing. We had to bring the new one quite a way because an anode bolted on the hull had caused the old plank to crack all the way through. Once that was done, the hole in the stern really began to close up, and suddenly she looked like less of a wreck.

The kindness and enthusiasm of several people has really made a difference. Someone here who owns a boat and who I barely know gave me a brass diesel tank and some other odds and ends from his old boat, which saved me from buying that! People get all enthusiastic seeing a wooden boat being repaired, and ask all sorts of questions. They aren't as common in France as I think they are in England, and the first query is "are you recaulking her?" It seems thats all they know about wooden boats here, that they need caulking. Actually, Petmar's caulking is in tip-top condition, not showing its age at all, so all we have to do is replace it where it has been removed around new planking. We are repaying the seams though. The mastic in there was plain linseed oil putty I think, and had hardened and cracked. Being replaced with red lead putty. Only the starboard side left!

On another note, there is a classic yacht festival in Boulogne from the 11th of July to the 14th (for the Bastille day celebrations), with tall ships, sail fishing boats, music on the quayside and plenty of food and drink. I will be present on Geoff the shipwright's boat Coppernob(1959 East Anglian). If anyone would like to come for the festival and enjoy the free mooring, drinks and meal on the Saturday night, let me know and I can fill in and send of the form for you, seeing as this is very short notice. (information requested: Boat name, type, size, year, number of people on bord-for meal tickets-, and any special features). It would be lovely to see some other Hillyards in the flesh (or wood!), and of course meet the proud owners.

Best wishes to all, hope you are enjoying the lovely

weather

we have had recently,

Abigail

Petmar arrived safely in Boulogne and the hull is almost

striped of all paint. The boat was emptied of all the

accumulated stuff

and the rusted balast removed. As the paint comes off it

is wonderful

to be able to view the beautiful planking and imagine all

the work that

went into it. Also, it allows my favourite shipwright and

myself to

identify problem areas and take a look at some of the old

repairs. Most

were of very high standard, with diamond pieces graved in

so neatly! It

is nice to see that someone cared for her a great deal. I

personally

have a softspot for the Elm half heart-shaped rudder! We

have soaked it

in linseed oil and wrapped it up to prevent cracking.

Unfortunately, it is this area (the stern) which

concentrates

most of the work, with one spot of rot going straight

through the hull.

Good job we didnt prod that one too much when she was on

the water!

Those bits of planking will be replaced. Reading the posts

on rot

caused by electrolysis, it seems that that is what as

happened in some

places, with old repairs simply rotting and the rot

spreading. There

were three anodes on Petmar: two on the rudder straps and

one diretly

on the hull. I will probably get rid of all when she goes

back on the

water and see how she fares without. Friend here has a

wooden boat with

no anodes and the prob/prop shaft etc seem to be doing ok.

We are just

careful to unplug the boat as soon as we are not on her.

She will be going into the shed on Friday for the hull

repairs, so the real work is about to begin!

All in all though, the more I work on her the more I like her, the cabins look better with all the junk out and the badly designed galley sink in the tip (someone added a sink on a pedestal at right angles to the original galley, which greatly reduced the space inside and looked rubbish). I can actually see the boat now, and I have spent some time down there daydreming already! I have the feeling I will spend many an hour simply admiring the beauty of the wood and the craftsmanship. I am one happy owner!

On another subject, does anyone happen to have the details of the people who owned her for 40 years or their family? I though they might like to receive some news of their boat and perhaps be relieved to know that she is being restored.

Many thanks again for all your comments above,

Abigail

Update - Monday 27th April 2009

Greetings to all!

Work is progressing fast thanks to the nice weather and

the shipwright

friend (can never thank him enough!). Unfortunately the

chandlery that

was supposed to lend us their hydraulic cradle on wheels

decided that

they wouldnt at the last minute so work is being done

outside on the

hard. This has led us to reorganise the schedule somewhat

as the sun

beats down hard and there is barely any shade. The hull is

drying out

and seams opening. To delay this I have already applied

the primer and

first coat of white above the waterline and will be

learning how to

repay seams this week to get the paint on below the

waterline asap.

Meanwhile, Geoff (the shipwright), has been getting on with the stern, which is really why I have come for your experience and advice today.

The area aroung the stern tube is completely rotten. This includes planking and the horn timer. Some repairs were made before, but only to the outside. As the whole area is open and accessible, I am considering replacing the stern tube for a stainless one to avoid electrolytic damage in the future. This would also mean replacing the rudder shaft and straps as well as the stearing fitting at the top, as galvanised and stainless just do not mix. The original stern tube is not badly corroded. The dilemna really is that there is limited time and getting such things made can take ages, simply because everything needs to be fitted exactly right and it will take a fair bit of time to be made. Also it will cost be quite a lot.

Has anyone else who has had this problem with the tube fitted a new one? If you haven't, have problems in this area occured again after replacing the rot?

For the moment I am leaning towards the do not replace side of the argument, and will probably keep the original tube if thats what seems to be the general trend. We will replace the wood and rebed the tube and hope for the best.

Thanks to all,

Regards

Abigail

Antipodes - 12 Ton

The twelve ton Hillyard Antipodes has now been laid up ashore for three years with little time for the owner to work on it as he is in the business! At present the cockpit and tanks are stripped out, plus the rudder stock tube and exhaust hull fitting. The tanks may well be rebuilt by Tektanks. While the ironwork has been partially and incorrectly replaced by a friend of a friend. Not such a good idea after all! Summer '09 afloat may be wishful thinking but Summer '10 is a must.

The owner Jonathan is on 01243-512494 for advice help and encouragement.

Jonathan has over 40 years of sailing experience and recalls David Hillyard from 1962/63 when his father was negotiating with him for 'Permission' to but a new boat.

Postscript

Jonathan, please can you drop me an email on hillyardyachts@ntlworld.com as I am working from a photocopy with some missing print and want to make sure all the above is correct.

Charlie - Restoration

Charlie is a 1960's Hillyard yacht under restoration in the Republic of Panama, where a top class wooden boat industry is being developed. Using skilled wooden boat shipwrights and superb local timbers at excellent prices, the boat is being given a face-lift. Originally, the Fernweh, that sailed from California to Balboa in the Republic of Panama, she had fallen into disrepair and was about to be scuttled until bought by Panama Yachting Services S.A. for restoration In March on the railway of the Balboa Yacht Club the hull was restored and painted and much of the deck replaced. With new mahogany planking, caulking, new pine decking under plywood the hull was made sound and she got fresh paint. A second time on railway concentrated on a new deck house and the interior. She is on her way to becoming a top quality Hillyard yacht again. Still to come are teak floors and a teak deck, made from Panama's local teak supplied by Panateak S.A.

Letona Update January 2009

The work on LETONA was very slow in getting started but now that the professionals are involved things have moved on apace. About 30m of mahogany planking has been replaced with oversized fastenings in the original frame holes. That was a job best left to the professionals, who will also caulk the new seams. I will plug the nailhead holes and pay the seams with putty, rub down and paint the entire hull: topsides, boot-topping and antifouling. I also have to replace a small section of the af terdeck and somehow cover that with the same kind of synthetic canvas that sheathes the rest of the decks.I have to fit new chainplates which I have had made, re-glue the mast sections and attach the standing rigging. All the brightwork needs sanded and re-varnished, there is a splendid Taylor paraffin stove which needs a thorough clean and polish. The Baby Blake head and the 12hp Petter both need servicing, the stern gland re-packed, water and diesel tanks drained and cleaned, new carpets and cusions made and fitted, rewiring and some internal joinery and a lot of painting and varnishing.

After a fit-out for the 2009 season she should be ready

to

go! There's nothing to it...

As aye

David

LETONA

Twenty years ago I persuaded my friend Howard Nixon to partner me on the restoration of a tiny little cutter called TEXA, which had been under a tarpaulin on the beach at Tayvallich in Argyll for as long as anyone could remember. The project took us nine months – that’s another story – but I am happy to say that TEXA is still very much in use, and that Howard and I are still friends.

Having spent the last few seasons skipping around Loch Sween in a petrol-powered Shetland, I was beginning to have notions about returning to the glory of sail. I was half-looking at GKs and Sonatas, thinking how much fun my family could have off Scotland’s west coast in something fast, safe and comfortable enough for overnight stops, without having to worry too much about maintenance.

I don’t spend much time on the internet, but have been occasionally compelled to scour the Projects section of boatsandoutboards.co.uk in the vain hope that something very useful might be going very cheap, very close to home. And in June, it was. FREE TO A GOOD HOME the advert announced – seducing me into clicking for more information.

The last thing on my mind was another wooden boat in need of restoration, but sometimes one must listen to the heart, rather than the head. A Hillyard 9-tonner awaited a new owner, 15 miles away in Ardfern. We went to look at her. All I could picture was the image of her anchored off Tiree sent to me by the heartbroken but pragmatic owners. All my wife Mandy could picture were the other images sent by email: sections of planking missing from sheer to waterline on both sides, afterdeck removed and hood ends sprung from the sternpost. All our daughter Niamh could picture was a vision of herself at the helm, dressed as a pirate captain and muttering nautical nonsense. She’s eight. We had a week’s holiday in Cornwall (where it is almost impossible to escape from boats) during which Mandy agreed to let Howard assess the project’s viability, and to be guided by his opinion. Well, you’re reading this in the HOA Newsletter, so we reached the right decision. LETONA has now been moved to A&R Way’s boatyard in Lochgilphead, where I will work on her as time, inclination and money allow. There’s a lot to do, but I’m confident that I can do most of the work myself. If I get really stuck I can call on the professionals, and I will certainly be very grateful for handy hints from Hillyard owners.

Letona on The Road

Gallant Maid circa 1969 11 Ton Hillyard Ketch Restoration

Gallant Maid is currently being restored by John Hamilton and June Cockton at the River Brede Moorings, Rye, East Sussex. All being well the plan is to have her back in the water by the spring 2008. As you can see by the photos punctuating this article there has been plenty of hard work put in to the project to date. June and John write, "I'm sure lots of other Hillyard Owners will only understand to well the love they have for their boats. Love, sweat and tears....."

" Who says Hillyards can't fly...." A photo of Gallant Maid being craned from the hard standing at her moorings to a nearby field whilst work was carried out By the Environment Agency on local flood defences. Note the trustee tyre on her bow that kept her covers on throughout the recent bad weather.

A further picture shows John ' King of the Corkers (sic. Caulkers) hard at work.

I am sure all Hillyard Owners reading this will offer their best wishes and support to this fine looking restoration project.

Singing Girl

- Project

Please see For Sale and News pages for more details or via paulholmes1956@hotmail.co.uk

Wanted: Portholes

Detailed below is a request form member Xavier Kormann owner of 9 Tonner Sarkl who is currently based in France

Hello,

We are French and we own a 12 ton sloop build in

1964 .Is

name is SARKL. We complete restored the boat: 60% of the

hull is new,we

used 5000 copper rivet,we also changed the decks and

roofs.

I like to change the portholes but I have difficulty finding them. Maybe would you be kind to help me for the search. They can be in stainless steel or brass. The dimensions are 600 x 200 4 units and 400 x 200 4 units

Thanks you in advance

M. KORMANN

Please contact Xavier via evasport@wanadoo.fr

Hillyard Ketch - SYLVIG ex. Gyngleboy

Please follow the attached link to see some stunning restoration images and associated story. An inspiration from new member Arne Sylvester - http://sylvig.dk

Alice - 2½-Ton

Part One

Owner - Will Fennell

Just to let you know my plan for my lovely little hillyard 2.5! Last year I purchased Alice, believed to be 1936, but definately a Hillyard 2.5. She was owned by the secretary at Aldeburgh boat Yard, Suffolk, where I am a boat builder. She hasn't been afloat for 3 years but I am in the process of giving her a quick spruce up so i can enjoy a summer with her for the first time.

At the Aldeburgh Boat Yard we specialize in classic restoration, mainly in the meter boat classes. Recent projects include 8 meter 'If', 6 meters Maida, Jo, Abu and Houri. 5 meter 'Indian', 50 sq seafart cruiser 'Hiltgund' and Alfred Mylne yawl 'Gudgeon'. Yard owner Peter Wilson is also currently building a modern (wood composite) 8 meter for himself.

A quick look over 'Alice' reveals that although she is a delightful little boat, she suffers from what I am told is a common problem in the 2.5 ton class, that of low standard joinery and general finishing. The hull however is in superb condition. The entire back bone is sound, no cracked timbers or floors and all well fastened.

Therefore my plan for winter 2006 is to 'lift her lid!' and replace the deck, coach roof and any deck beams which refuse to part company with the current, rather flimsy deck. I also plan to fit a very small inboard diesel engine with offset prop, and maybe if my budget and spare time will stretch to it, a hollow wooden mast.

I was pondering replacing the coach roof from the moment i got Alice, but I was swayed when the current owners of the afore mentioned Mylne yawl 'Gudgeon' handed me a Tesco bag with 4 bronze port holes in it! Not only are they simply fantastic to look at, they were the 1920 originals from gudgeon which the surveyor rejected during the restoration, despite having twice been trans Atlantic! So Alice having square windows, of course needs a new lid to fit round ones, decision made!

I will endeavour to keep you informed with words and

pictures

during next winter and of course if you or any other HOA

members are in

Aldeburgh please feel free to drop in. There is always

something

interesting going on!

Regards

Will Fennell

Aldeburgh Boat Yard Co Ltd.

Part Two

I'm not sure whether to call this project a restoration? I think a project becomes a restoration when and if the deck comes off the boat and in this case I have stopped just short of that!

I took Alice out of the water when the very expensive bilge pump I installed which was keeping her afloat packed up. Having sailed the entire summer with a more than damp bilge I started to get an idea of what I was in for this winter/spring.

As soon as Alice was out of the water I took the opportunity to drop the keel off. All the nuts came off the bolts with no real problem and before the boat was dry from her scrub the keel was on the floor. The hard crumbly layer of white lead stuck to the bearing surface of the keel showed immediately the cause of the wet bilge. what was probably a good soft seal between lead keel and wood keel 70 years ago is now a chocolate tea pot.

After giving the keel bolts some welly on the anvil they showed no sign of deterioration or metal fatigue so will be reused in the spring. With no room for Alice in the shed I have had to build a tent over her outside. This has worked really well so far standing up to a nearly full gale.

The first job in the tent was removing the coach roof. this was quite quick and was shortly followed by the cockpit and 3 bulkheads. All have been kept in one piece for patterning because they were nicely fitted but very tired.

I started stripping the layers and layers of paint from the cockpit area and when I had done so I had a good poke at the areas susceptible to rot. I found the usual water logged timber ends and some over generous use of sitka flex on the hood ends, but the real heart sinker was the stern knee. From my short season sailing Alice i knew there was a leak from somewhere around there. Some good poking with a screwdriver showed the stern knee and floor on it to be very soft indeed. I decided I would never get a better opportunity to replace it, so out it must come. The 5 bronze bolts all came out easily bar one, which had to be drilled out. lots of screws were taken out of the planking near the hood ends, and after some grunt with a prise bar the knee popped out.

I'm glad I did take it out because all the bolts holding it in fell apart on the anvil, the stern post was behind the knee was wet and the knee itself had seen much better days. The stern post is now drying out nicely and I have made a new knee. when I am satisfied everything has dried out well and I have done the necessary work on the hood ends I will fit the new knee and repaired floor. I will fasten with new bronze bolts and bed on sikaflex.

I will try to keep you up to date. Sorry about the

essay,

please feel free to edit where you feel necessary!

Regards

Will Fennell

6th November 2006

Part Three

Quick update on Alice. All floors have been removed,

repaired

and refastened, mast compression post removed and replaced

with ring

frame to free up cabin space, complete repaint inside, all

seams

cleaned out underwater, timber ends replaced where

neccessary.

Will Fennell

4th July 2007

Allan Lindsay

My wife and I were smitten by the Allan Lindsay's lovely lines when we first got a glimpse of her at the Poole Yacht Club on a cold day in April of this year after driving down from Cambridge to have a look at her. The Allan Lindsay, a Canoe stern 6 tonner, (28 feet, beam 7ft7in, draft 5 feet, bermudan) with a centre cockpit built in 1957 of mahogany on oak, had been slowly deteriorating at her berth in Poole for the last eight years and was now up for sale.

Despite our growing panic at the amount of rot we found and our inexperience (The Allan Lindsay is our first boat), we were determined to have her. An offer was made and accepted, and, with the encouragement of Michael Walden, Commodore of the Hillyard Association and many others. we began the restoration of the Allan Lindsay

Winsome Lady

Brynhildr

Michael Walden suggested during his visit that I contribute some notes for the newsletter on what I have been doing during what has turned into a very long drawn-out refit. Much of the work has been intended to make her more efficient both under sail and under power, particularly if short-handed: in part due to the competition for space on the water these days: also to reduce maintenance in what is quite a sever climate. The changes to her general appearance and character are minimal.

General Comments

As I do nearly all the work myself I use materials and fittings which I think are most suitable or which can be adapted. Also, I keep a lookout for things which may come in useful (an inherited habit!). I have a Davey & Co. catalogue of the 1920's and it is clear where BRYNHILDR's fittings came from - how easy it was in those days. Not just in those days, a few years ago a local galvaniser lost two bollards and Davey & Co. were able to supply identical replacements. I have recycled as much original timber, and used existing holes in the structure where possible. I have also used plywood where appropriate (e.g. for hatch covers and locker bases).

History:

Built 1933 to my later father's order and brief

specification. From memory I think he said the cost was

£760 (of which

about £100 was for the engine and £5 for the dinghy - 10

Shillings per

foot!) ready for sea. I still have the dinghy, but rarely

use it.

1933 - 1957: West Coast of Scotland

1957: Shipped from Port Glasgow to Sydney, Australia

following the

families relocation in 1955.

1957 - mid 1970's: Sydney Harbour, mostly weekend sailing.

Mid 1970's to date - maintenance only initially, then

major refit with

occasional use under power. The longest period out of the

water has

been about six weeks.

Steering:

Some years ago I increased the efficiency of the rudder

by

almost eliminating the gap between rudder and transom,

slightly

reducing the propeller aperture in the rudder blade, and

tapering the

training edge of the blade. I can thoroughly recommend

this for transom

hung rudders.

Last year I made a tiller lock, which seems to work well

but required a

new tiller. A 10mm nylon hole attached to each toerail,

passes through

a series of five 10mm holes or eyes in a fitting built

into the tiller

about two handbreadths from the end. Numbering these hole

or eyes from

one to five: 1& 5 are holes in brass cheek plates

recessed into

each side of the tiller, 3 is a fixed eye in the centre,

and 2 & 4

are eyes on a block which is moved fore or aft by a rod

threaded in a

knob (in effect a nut) on the end of the tiller. Turning

the knob,

which draws eyes 2 & 4 towards the tiller end jams the

tiller line.

Ballast:

I had thought for a long time that BRYNHILDR was rather tender considering her hull shape. I have lowered the centre of gravity if the internal ballast. The effect was noticeable even when moored, confirmed under sail 9th November 2000.

Spars and Standing Rigging:

The spars are original: the boom and gaff were shortened in 1935 when a cloth was taken off the leech of the mainsail. The mast was unnecessarily tall; I have taken 2ft-6in off the head and lowered the hounds 5ft (but not the forestay). Backstays now give additional support to the forestay terminating just inboard of the toerails about 5ft 6in aft of the mast on travellers on a stainless steel bar, controlled from the cockpit. I studied published designs and many books, from Dixon Kemp and Claud Worth to Tom Cunliffe before making any changes.

Sails:

A new polyester mainsail, not as high peaked as the

original,

is now in use, and a 1960's flax staysail. I have fitted

two of the

original three tan cotton jibs with hanks. A stay, to

which a jib is

now hanked, is attached to a bowsprit traveller. The

geometry of the

rig enables the stay to be set up taut by the outhaul. The

jib can be

set, or lowered and held down by a downhaul, from the

mast. The jibs

never had as much use as the other sails; even after sixty

seven years

they still have a pleasant aroma when warmed by the sun.

Running Rigging:

All halyards and sheets (except headsails at present)

are

synthetic. Headsail halyards are low-stretch rope; small

winches for

these have been fitted to the boom gooseneck mast bands.

The throat

halyard now has a single block with becket at the gaff

instead of a

double, which gives the same purchase as peak halyard.

Coiling away

after setting sail is now much quicker.

The above is a brief outline of some of the work done so far. If any members would like additional information, whether mentioned here or not, they are welcome to contact me direct.

9 Ton

Howdy Hillyards association, found your website a while

back

and it has been great to look through the pictures and

info. Especially

to see some of the restoration projects. I have just

recently purchased

a Hillyard 9 tonner. She is in North Carolina and I live

in New

Hampshire so I plan to move down there to work on her this

upcomming

winter. She has been out of the water for 8 years and

needs a whole lot

of love. I'm really excited for this project and fell in

love with the

boat when i went down to visit her. I guess I just wanted

to let you

know about this project that im so excited for. If you

want to post the

pictures of the restoration on the site that would be

cool. I have a

ton of pictures as she sets right now.

Take care Joel

Joel's 9 Ton Hillyard